MSR has extensive operational experience in the Puna region. In the towns of Campo Quijano and Olacapato in Salta, MSR has : roads, electricity, gas pipelines and fresh water supply. These production support plants are available to be used for the project. MSR also has a camp easement to house the workforce in charge of mining activities at its eight properties.

In addition, MSR hasan efficient logistics chain for the development of its operations. Its operational and logistics capacity is so extensive that MSR offers mining services to other mining companies in the area (such as Posco, Borax Argentina S. A. and Mansfield Minera S. A.) in their exploration operations.

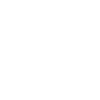

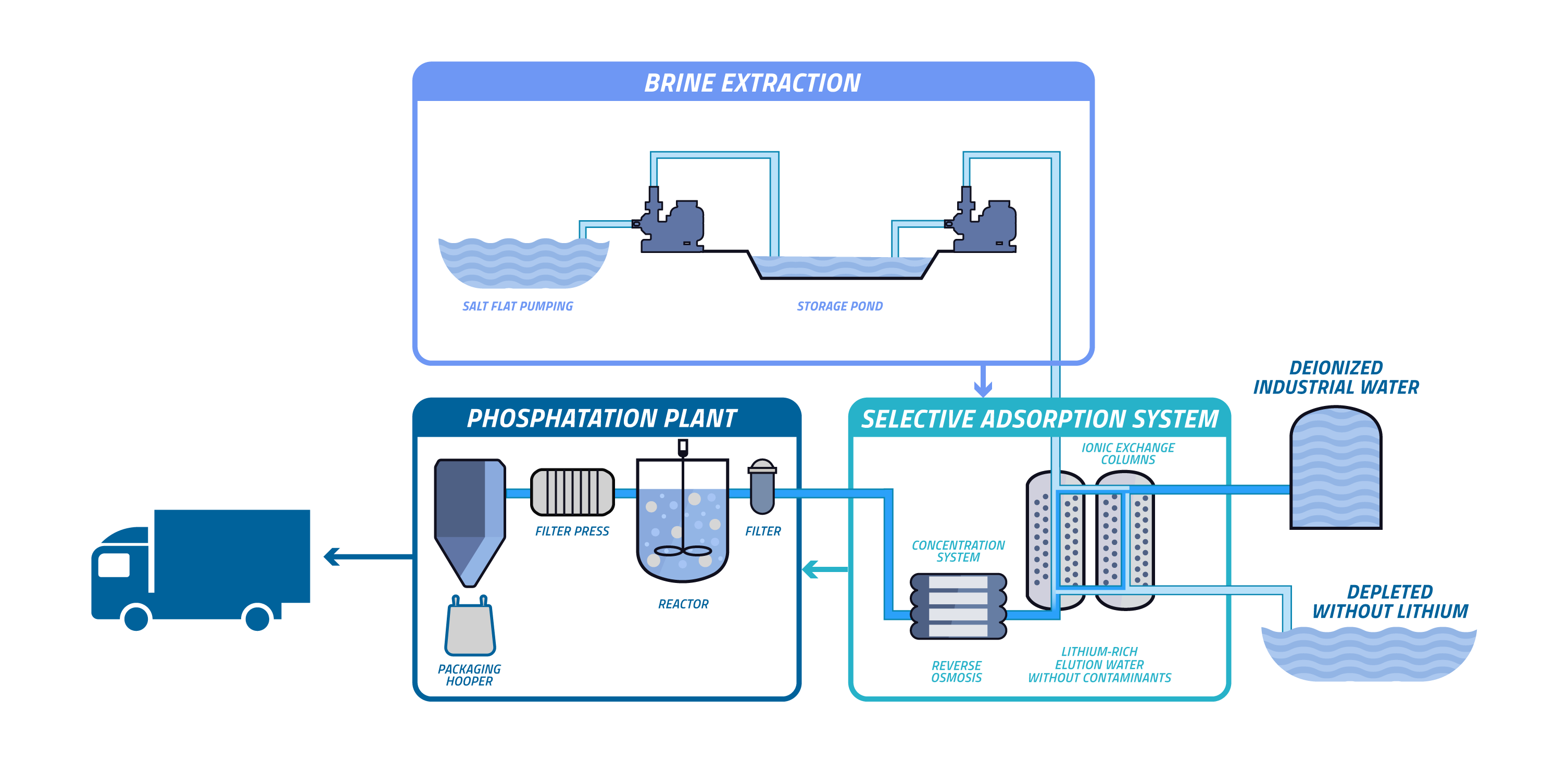

Other essential components for the project include the storage warehouses and a top-notch analysis laboratory. All these elements enable the development of its main operations: the extraction of lithium brine, its transport to the production plant, and the production of lithium derivatives.